Humidity Cell Testing

We undertake Humidity cell testing in accordance with the ASTM D 5744-18 standard. The ASTM humidity cell methodology is an accepted procedure to determine sulfide oxidation rates and for the prediction of the lag time to onset to acidification ('the kinetic characteristics') within granular mining wastes. The method is accepted and in keeping with the following international regulation and guidance documents:

The ASTM method is summarized as follows:

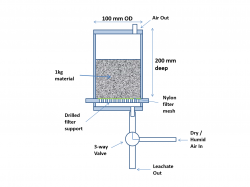

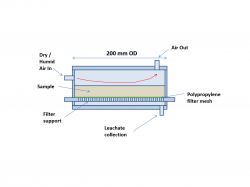

- A sample of material is crushed or screened to a particle size less than 6.35mm (1/4 inch). A representative sub-sample of this material of known weight (usually 1 kg) is carefully loaded into a cylindrical cell usually of 100 mm internal diameter constructed of clear acrylic plastic.

- The cell is constructed in such a way as to allow air to be circulated through or over the granular material and to allow for leachate to be collected from the base. This is shown in the schematic diagram at the base of this page.

- The humidity cell is run on a weekly cycle of three days dry air, three days humidified air with the cell being flushed on a weekly basis with deionised water (seventh day).

- The leachate generated on the seventh day flush is collected and analysed for basic electrochemical parameters of pH, electrical conductivity and redox potential. In addition alkalinity, acidity and sulfate are also determined to track the oxidation of sulfide minerals and depletion of carbonate minerals within the cells.

- Sub-samples of the collected leachate are commonly sent for analysis to determine the elemental solute load released from the material during the test period.

- The weekly cycle is repeated for a minimum of 20 weeks. Longer periods are often necessary as it is important that stable conditions of pH and sulfate release are reached.

A number of adaptations to the ASTM method can be undertaken depending on the particular sample characteristics. For example, the ASTM methodology indicates the following variation:

- Amendment of circulating gas composition (i.e. addition of CO2)

- Variation in cell diameter

- Variation in air circulation and humidity characteristics

- Volume of leaching solution used in weekly flush

- Application of preliminary flushing to remove soluble salts

- Determination of oxygen consumption and carbon dioxide release within the cell.

All test variations can be accommodated within the Geochemic laboratory facility.